Onedrive Documentation

All planning and production files have been saved to Onedrive for easy access. If you are a current student making revisions to the design, this is for you.

dtrusko@gmail.com | (415) 860-5126

Developed for the ASU Polytechnic's Engineering Department

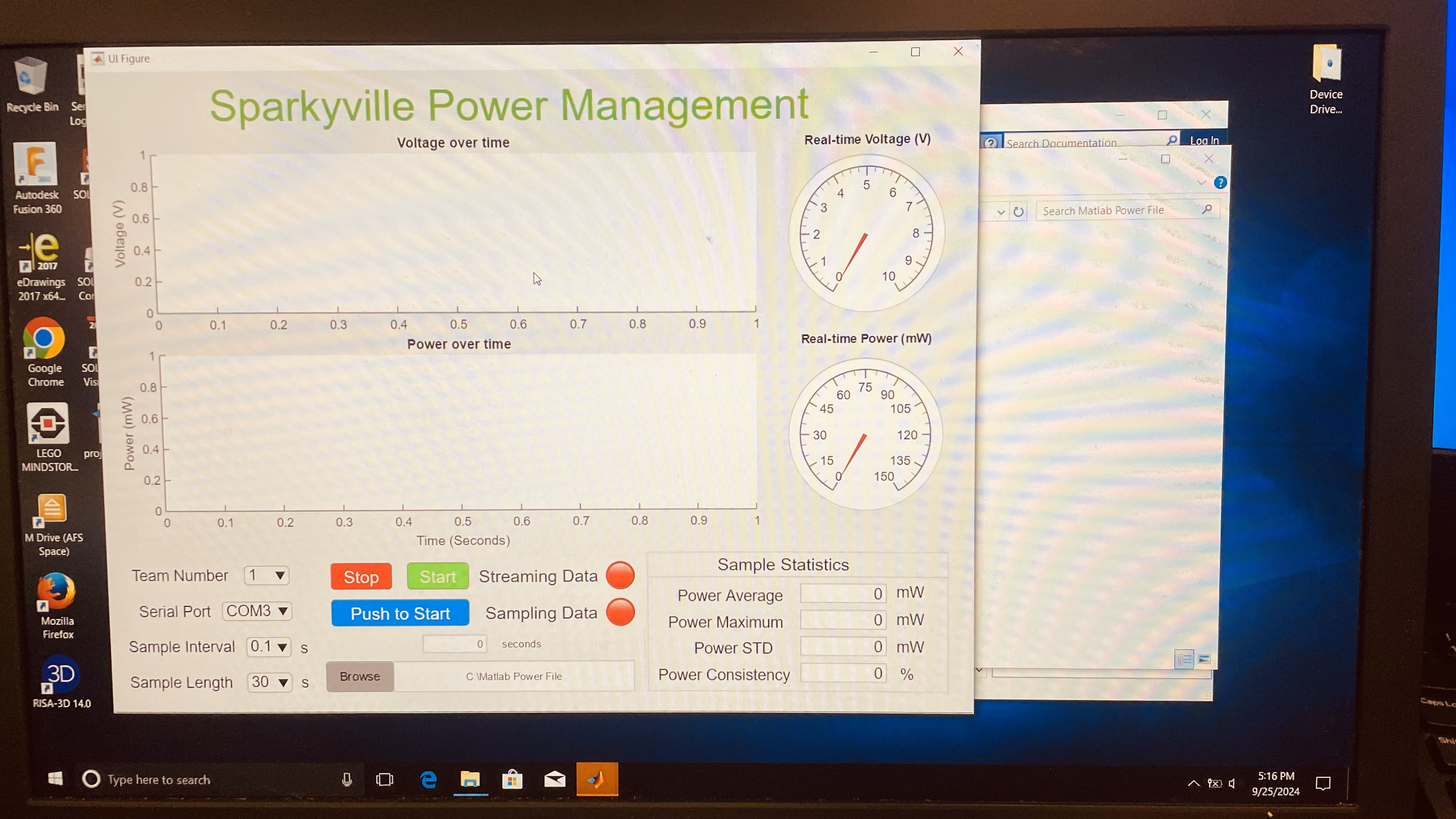

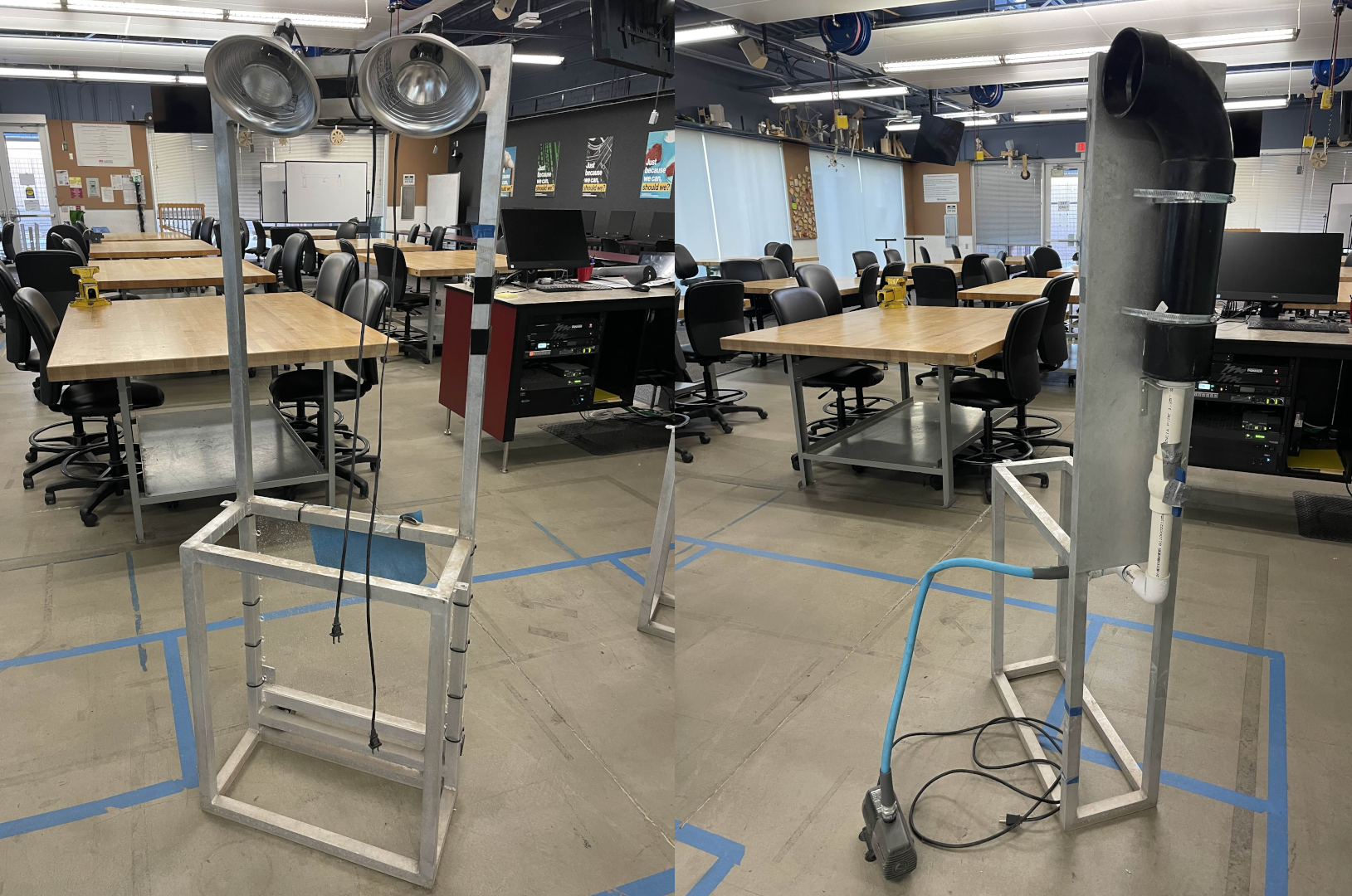

The Problem: To learn mechanical design, and introduce electrical work to students, the ASU Polytechnic school has a project for introducing these principles to first-year engineering students. Pupils are tasked with designing a power generator using one primary power source (Water/Wind), and a secondary power source if desired (Solar). To test their generator, the students would plug their generator into a Raspberry Pi mounted within an acryllic box, which would then be digitized and sent to a MATLAB simulink instance running on a school-provided laptop. Labview would then read the data, and produce a visual to indicate the performance of the student's projects. This project has been run every year, until 2025 where a background windows security update finally bricked the laptop.

Design Considerations: The first goal was to meet with the program professors to ensure we are hitting all their desired features, as well as getting a rough estimate for the budget. The following requirements were laid out by the teaching team for a replacement.

Given these requirements, we were also given limitations to ensure it would meet the requirements laid out by the program.

Ideation: The requirements for this project immediately made me think of Programmable Logic Controllers (PLCs). The necessity for reliability, combined with the harsh environmental conditions, made this solution shine in comparison to other options. I had experience programming PLCs, so it made perfect sense to go this route. After comparison shopping and reaching out to local companies to try to get donations we finally settled on using an IDEC FT1A-Touch. This PLC features a touchscreen interface, which means I already have easy access to one of the project requirements. While they generally retail for ~$400, a local company offered to donate a demo unit for our project. IDEC also graciously provided their software as we are a student organization.

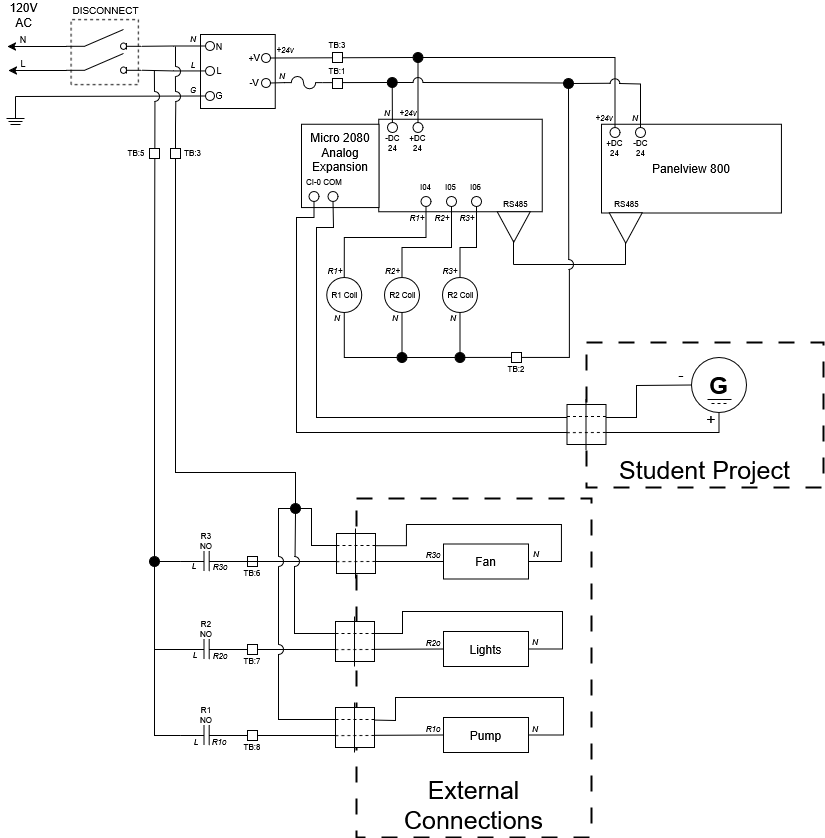

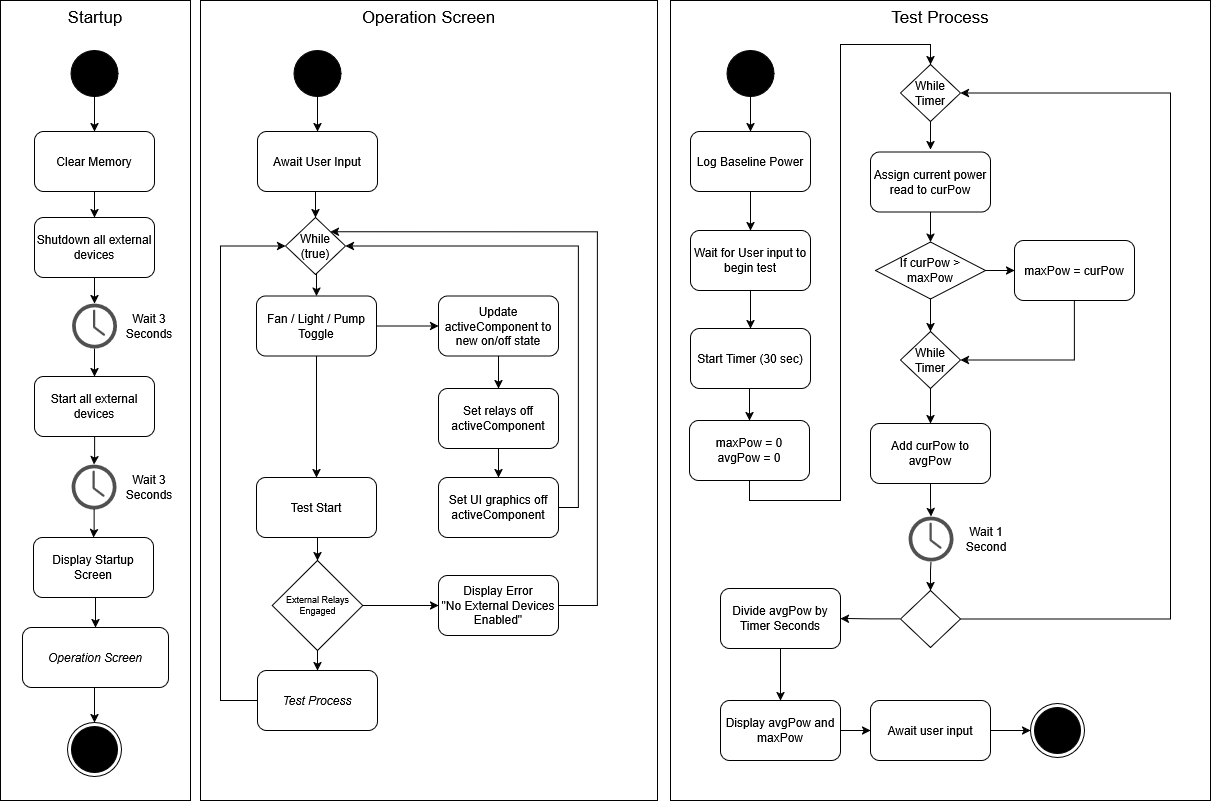

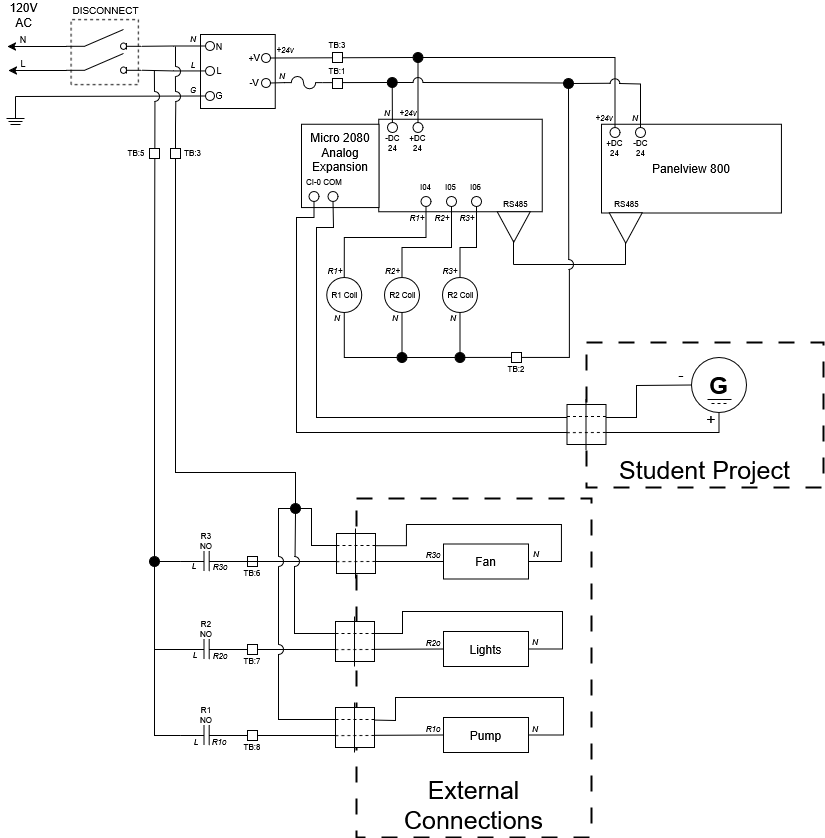

We then started on a UML programming diagram. This helped understand the hardware requirements by moving through the logic. While this is far from the final software design, as many other problems came up during fabrication, this was a good stepping-off point. Following that, we got to work on the wiring diagram. This wiring diagram covers the final hardware as selected, with the exception of the PLC. Our original design involved using an Allen Bradley Micro 2080 with a Panelview Touchscreen, but due to a sponsor dropping out we had to replace it with the final selection.

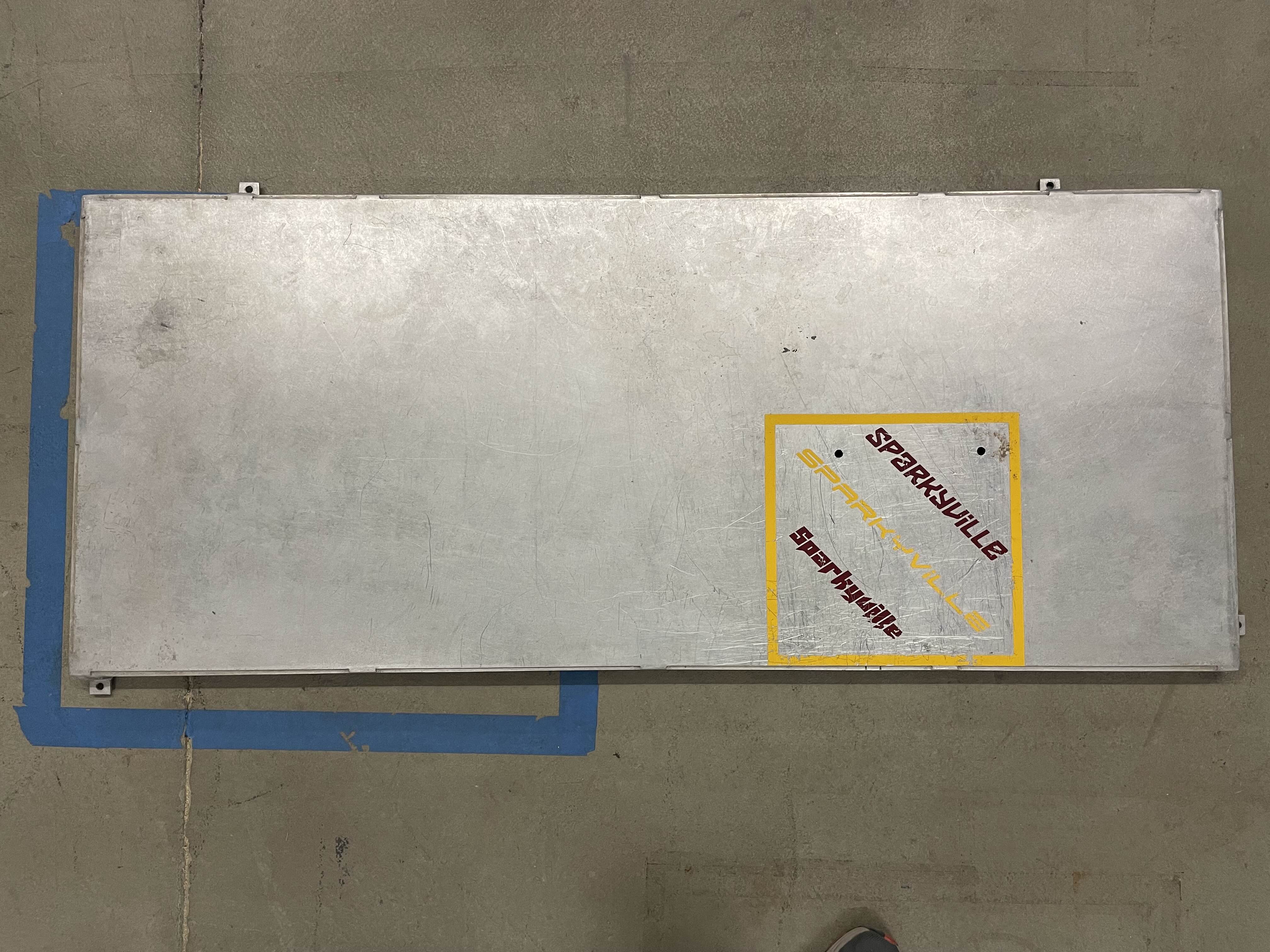

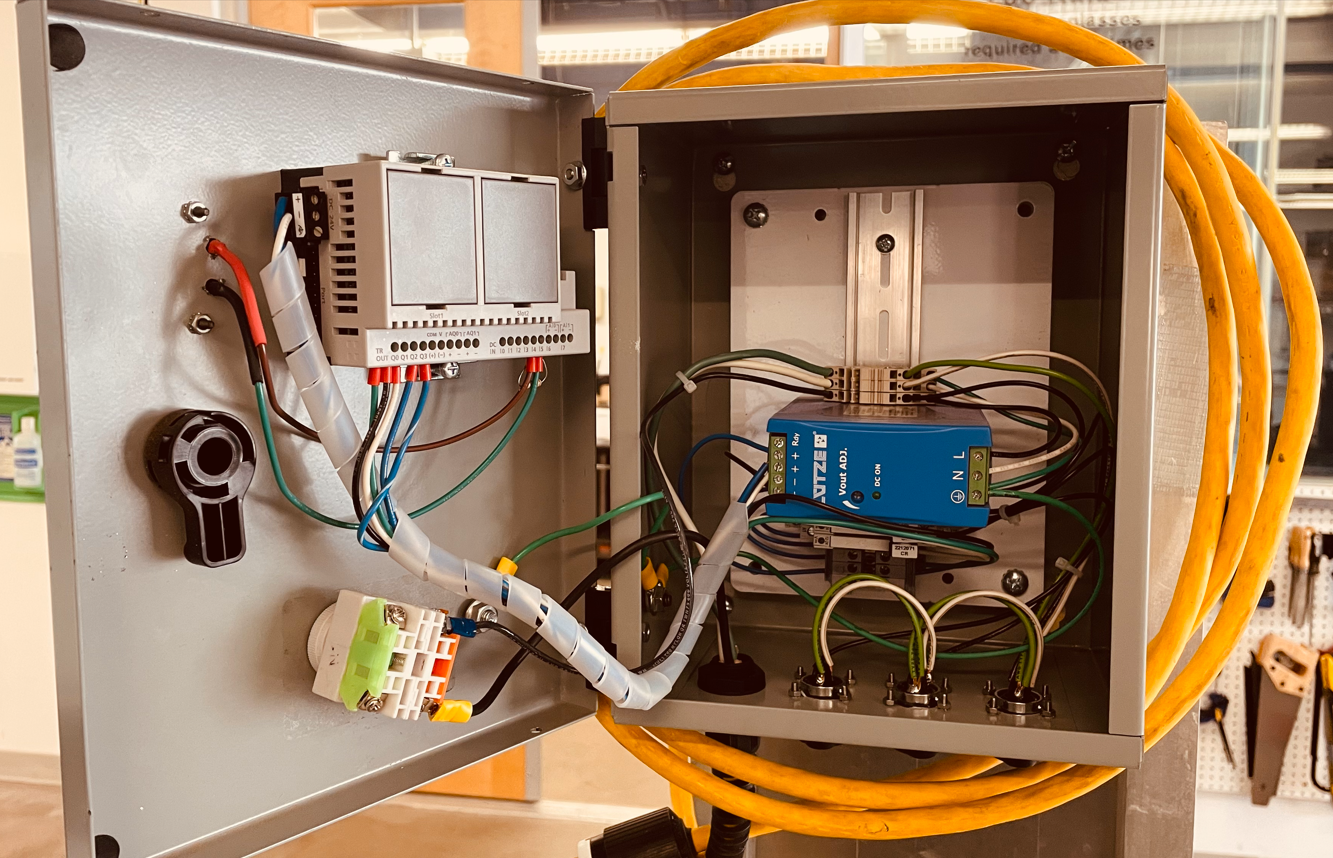

Final Build: While reaching out to local companies I made an interesting discovery. Many manufacturing companies are starved for skilled employees. The reception from my public outreach as incredible and extremely impressive. We managed to design and construct the entire project exclusively from donated hardware, using none of the budget allocated for the project. This money could now be reintegrated into the cirriculum. Our final hardware list was a grab-bag of equipment that was donated, much of it without names or part-numbers attached.

To see what the final project looks like, check out the 3d scan included at the top of the page. Below are pictures of the interior of the panel, as well as a video of the touch-screen interface I designed.

Post-Mortem: I learned a lot working on this project. Not only about PLC programming, which was my target area of improvement, but also interfacing with businesses. Talking to individuals along the entire production process from design, sales, and fabrication to learn how to correctly integrate the donated hardware. I am extremely proud of the final project, as it taught me a lot about UI design, PLC programming, panel-design, weatherproofing, and various other skills. We manages to hit all of our target requirements while using none of the budget. I will bring other members from my club in to do some beautification passes, such as sanding the dirty aluminum table to reseal it, as well as add wire-channels to make it easier to move and lower-risk of breaking from long-term usage.